INDUSTRY

PMC\AVI system

- Categories:Industry section

- Time of issue:2021-09-26 12:56:44

- Views:0

• PMC solution

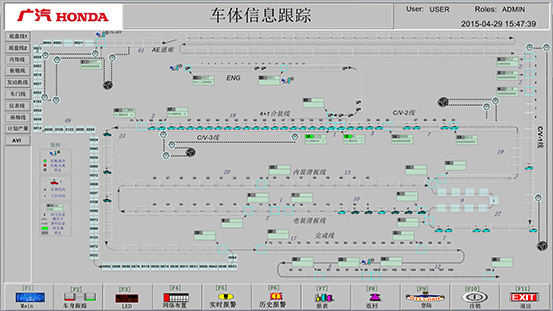

The core of PMC (Productionmonitorcontrol) monitoring system is the application software for real-time monitoring of automobile process parameters, which is completed after secondary development on the basis of configuration software. Developers can develop PMC software suitable for workshops such as stamping, car body, painting, and final assembly according to the equipment process characteristics of different workshops. This system allows the operator to see the status of each system, the site and other related information components in real time. At the same time, it also displays the connection status between the application systems. The operator can also click the corresponding station area button to understand its operating status and parameter values.

• AVI solution

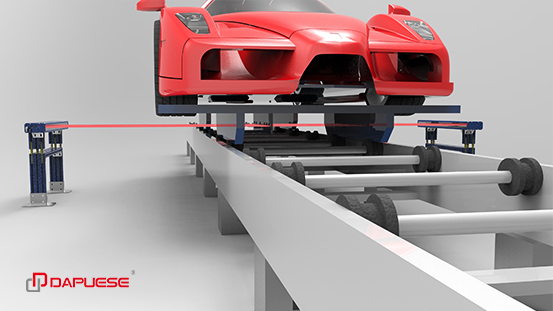

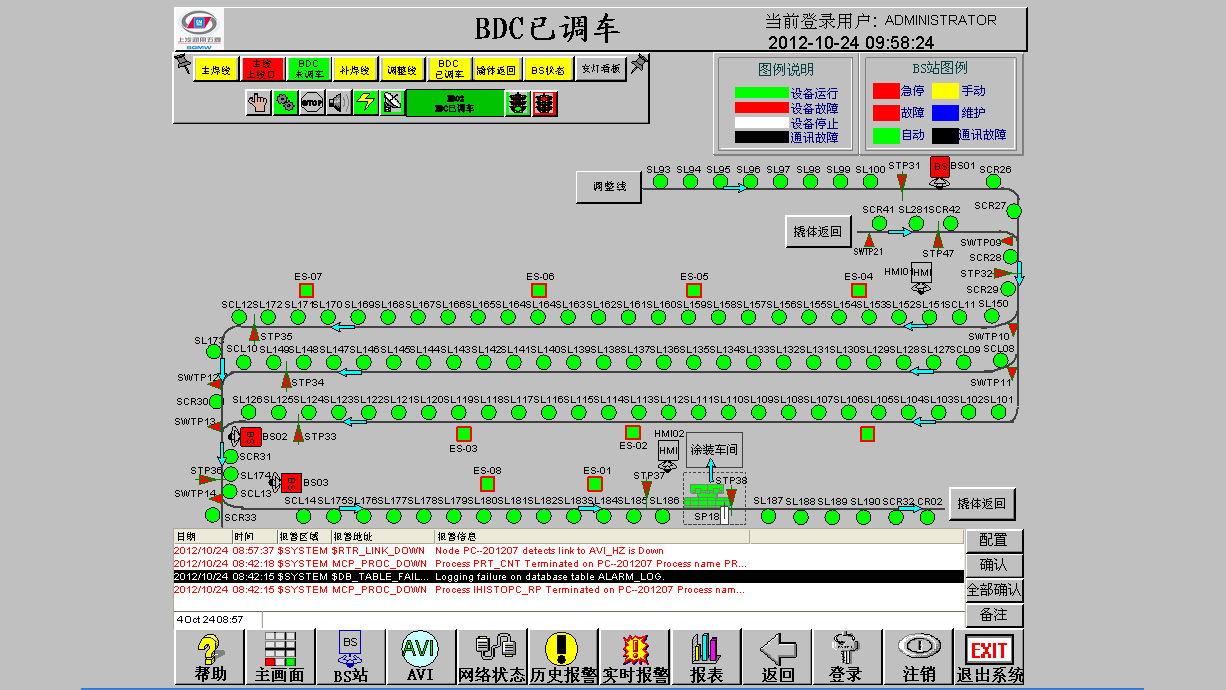

The body recognition/body tracking system (AVI) monitors the movement and processing of the processed body in the body shop, the body-in-white storage area, the paint shop, and the body storage area after painting and the final assembly shop. The car body recognition/car body tracking system detects the type and movement of the car body by collecting the signals of the limit switches, barcode scanners and other sensors installed on the site, and creates a tracking model and records the movement of the car body in the server computer. We provide a complete set of solutions and custom-developed a code reading device, a steel bar code reading station.

• PBS scheduling system solution

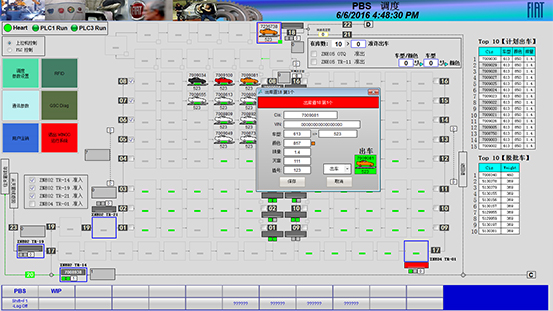

In modern automobile production lines, it is often necessary to reserve a vehicle buffer area (that is, a temporary vehicle storage area) between painting and final assembly. Through this buffer storage area, the upper layer can realize the vehicle as planned through production planning tasks. According to the steps, the production is carried out in an orderly manner. Therefore, the significance of this vehicle storage area will become very important, it is related to the scheduling efficiency of the entire production system, production rhythm, and product quality, etc. Based on this buffer storage area, and to maintain and monitor this storage area, we define this system as the PBS system (PBS is the abbreviation of Painted Body Store). The PBS system is an intermediary buffer area connecting the painting and final assembly process of the automobile production line. We developed the PBS system at FIFT Fiat and other sites, which perfectly solved the problem of vehicle buffering.

• ANDON flexible interface

We not only research and develop stable and reliable hardware equipment, but also continue to develop in-depth on the soft interface. Several ANDON softwares that we have developed have been designed to reduce the complexity of a user-centered interactive system. This "simplification" is an almost ideal state in the human-computer interaction discipline, with the goal of establishing a simplified interactive system. The design will become a kind of existence that subtly enhances some of our human abilities, not just as a soft control paired with hardware, let us work together to build "Industry 4.0" and "Made in China 2025" smart factories.

Telephone: 86-510-85160390 / 85160395

Pre-sales/After-sales: 86-13382891299 (Mr.Zhu)

E-mail: zjm@dapuese.com / zwbemail@163.com

Address: No.10, Hengliang Road, Outang Town, Huishan District, Wuxi City, Jiangsu