CN | EN

About Dapuese

More hot topics

2023-01-03

2022/02/16

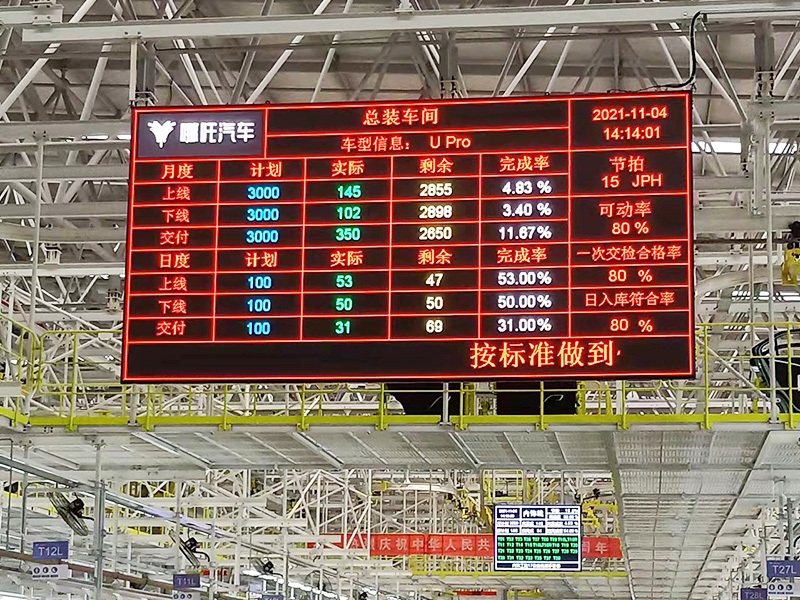

Functions of the MES Management System

The MES Management System is a solution system for manufacturing enterprises to monitor and manage production information at the shop floor execution level. Generally, a complete MES management system should include the following modules: manufacturing data management, planning and scheduling management, production scheduling management, inventory management, quality management, human resources management, work center, equipment management, tooling management, procurement management, cost control, project dashboard management, production process control, underlying data integration and analysis, upper-level data integration and decomposition, etc. The MES management system can create a stable and reliable manufacturing collaborative management platform for enterprises. Let's take a look at the functions of the MES management system.

1. The MES management system can manage the shop floor on-site.

The MES management system can manage the construction site, including production management, construction operations, initial inspection applications, final inspection applications, material distribution applications, and other management content. Employees can print task orders, complete reports, and perform inspection reporting through self-service terminals.

2. The MES management system can track product/production line freight logistics.

The MES management system uses barcodes, RFID, DPM codes, and other methods to track product freight logistics and grasp the status of work-in-progress.

3. The Manufacturing Execution System can monitor equipment status.

The MES management system monitors equipment operation and normal production processing, analyzes equipment utilization in real-time based on the DNC module, providing a basis for improving equipment utilization.

4. The Manufacturing Execution System can analyze and monitor quality management.

The MES management system prevents errors and leaks during the production process by comparing with standard procedures. It reports and handles quality issues, analyzes quality problems over a period, and generates various quality management reports.

5. Manufacturing Execution System Quality Process Management

The MES management system can track the entire inspection process and product quality, strictly controlling the entire process and rectification of non-conforming products. The MES management system mainly achieves recording of key factors during production and complete traceability of product quality, accurately measuring product pass rates and defect rates, bringing quantitative indicators to quality management. Based on product quality analysis results, preventive maintenance is performed on the manufacturer's products.

Previous page

Phone:+86-510-85160390,85160395

Pre-sales/After-sales:+86-133 8289 1299(Engineer Zhu)

Email:zjm@dapuese.com/zwbemail@163.com

Address: No. 10 Hengliang Road, Outang, Huishan District, Wuxi City

Copyright © 2021 Wuxi Dapuese Electronic System Engineering Co., Ltd.