CN | EN

About Dapuese

More hot topics

2023-01-03

2022/05/06

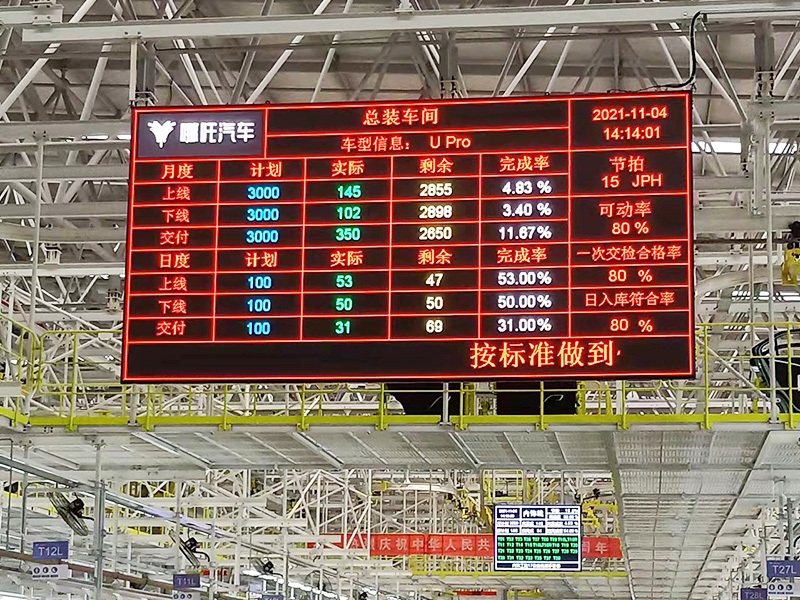

Knowledge of ANDON System Visual Management Board Classification and Board Functions

The ANDON system, as a visual management tool for the production site, allows real-time understanding of the workshop production status through electronic boards, enabling management to access relevant production information via the electronic boards and respond promptly to abnormalities. ANDON System What are the categories of electronic signage? Below is a summary of some commonly used board information for your reference.

1. ANDON System Material Electronic Board

In the warehouse material area and the main distribution screen, it displays real-time outbound time, production line, outbound material information, material requirements, outbound information, and expired waiting content; it can guide material preparation and distribution in real time.

2. ANDON System Equipment Maintenance Electronic Board

In a prominent position at the equipment technical department, the equipment maintenance board displays call time, production line, equipment code, equipment name, whether stopped, maintenance technician, time, daily status, and other equipment information, allowing maintenance personnel to quickly locate repair information.

3. ANDON System Demand Electronic Board

On the large screen in the office area, it displays call time, production line, caller, expiration time, current status information, etc., allowing viewing and understanding of the production line status.

Main functions of the ANDON system electronic board:

Quality Abnormality Function: On-site production workers can use the on-site board to alarm for problematic product parts or defects, so that relevant quality management personnel can obtain information and handle it, avoiding losses caused by products. Delayed delivery.

Equipment Abnormality Function: On-site production workers can use the ANDON system on-site board to alarm equipment failures, with red light indicators and email notifications to on-site staff and related management personnel; this allows relevant maintenance management personnel to obtain information and handle it, avoiding losses caused by delivery delays.

Material Abnormality Function: On-site production workers can use the on-site board to alarm for related material shortages, allowing relevant logistics management personnel to obtain information and handle it, avoiding losses caused by delayed delivery. Historical issues are summarized in the background for easy analysis and review.

Real-time Production Volume Display: You can understand the planned workload and actual workload completion status of all production processes on the ANDON system board; it is displayed on the on-site large screen board, allowing timely comparison of work progress, notifying relevant responsible personnel promptly when problems occur, and forming a historical comparison chart of actual workload versus planned workload.

The ANDON system electronic board system is an effective integration of all links related to product production. Through the system's board prompts, the goal of just-in-time production is achieved. If you have any views on the visual board management of the ANDON system, please follow, comment, and discuss together.

Previous page

Next page

Phone:+86-510-85160390,85160395

Pre-sales/After-sales:+86-133 8289 1299(Engineer Zhu)

Email:zjm@dapuese.com/zwbemail@163.com

Address: No. 10 Hengliang Road, Outang, Huishan District, Wuxi City

Copyright © 2021 Wuxi Dapuese Electronic System Engineering Co., Ltd.